1D CUTLIST OPTIMIZER DOWNLOAD

To appreciate the potential of the program we invite you to download the demo version or the App OptCut Free from Windows Store. Is possible then repeat the optimization by varying the parameters to get the best suited to your needs. Also if for each panel is inserted the material cost, the edging cost and manifacture cost cutting cost or other costs the program allows you to do the cost analysis of the job. The program, starting from the available materials, from pieces to manufacture, and technical restrictions blade thickness, possible rotations, machine limits etc. The first objective of the program is to minimize scraps allowing substantial savings in material and gains in productivity.

1D CUTLIST OPTIMIZER SOFTWARE

Testimonials "I cannot believe how well this software works!OptCut is particularly suitable to production companies such as furniture manufacturers, joiners, marble workers, glassworks, etc. Amd ryrtx 2070 super bottleneckĪnd as the program allows for dates of jobs and materials used, it can also be used as a very simple and basic quoting system. It gives the operator the complete graphics of the cutting required on a particular job. All our locations have responded very positively and all were up and running witn hours of installation.Īffects your bottom line in such an easy, instant and dramatic way! There's not a lot of software in this price range that affects your bottom line in such an easy, instant and dramatic way.

1D CUTLIST OPTIMIZER HOW TO

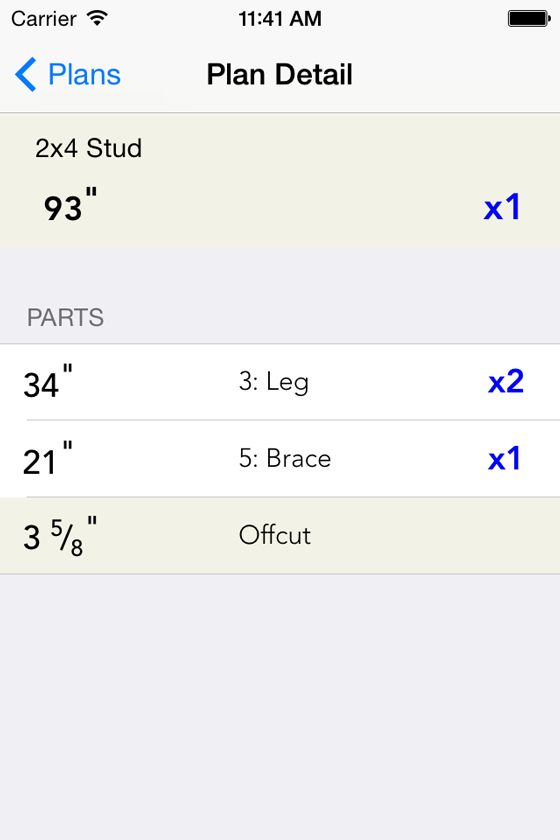

Fastcut takes the guesswork out of determining how much material we need, and how to cut each panel for maximum utilisation of the material. Other thermal or mechanical cutting processes usually result in a finite loss of material which can be specified as Kerf Width Allowance.

Kerf Width Allowance: For a shear, guillotine, cropper etc. Job costing calculator produces material cost and return to stock. Optimizes Remnant before using Standard size Stocks. Works with Coil as well as Sheet and Bar! Choices for stockfeed are: 1. Alternatively, all offcut can be defined as scrap. Stock consumption can be prioritized by nominating some items as pre-existing remnant, which forces the use of non-remnant stock where possible. The program will break down the amount of material into that being used, that which needs to be returned to stock, and that which is scrap. Nesting can also be interrupted at any time for review of results to date. Nesting can be terminated after a specified time has elapsed, or after attaining a specified scrap factor scrap mass expressed as a percentage of total mass of parts. It can, in fact, test a whole range of processes over a different range of sheets and the operator can see the sheet layout on the screen.

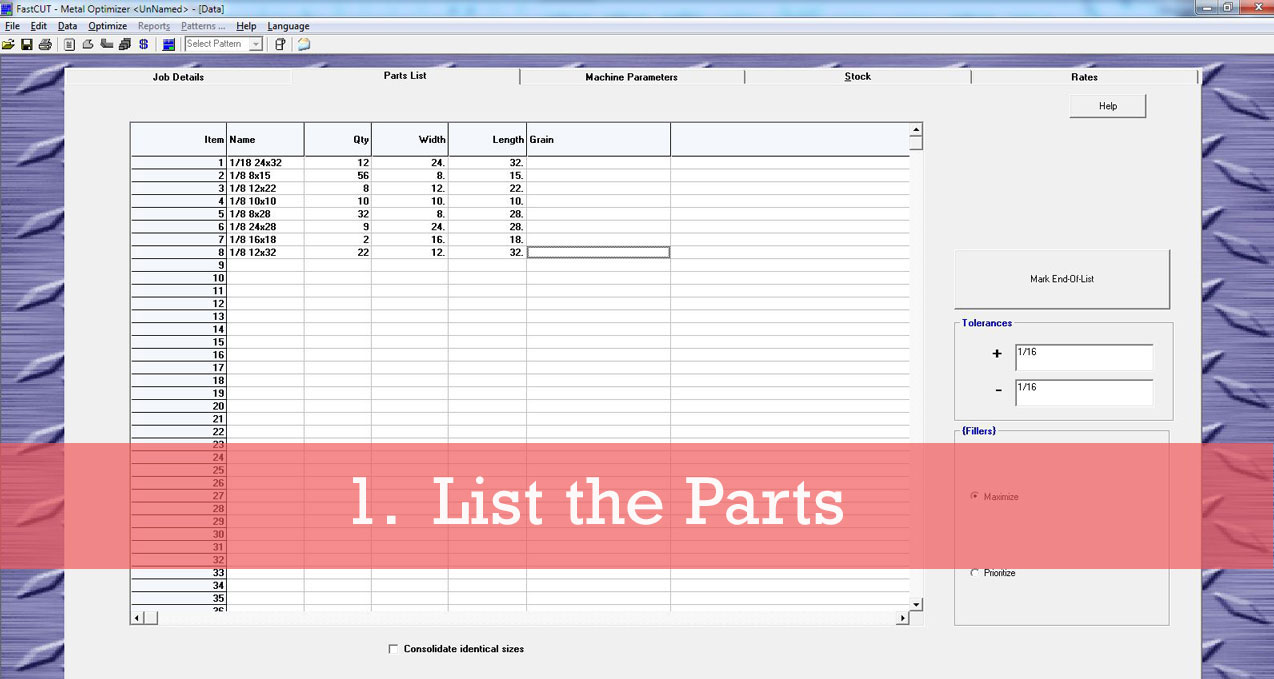

It will then process the part variations within sheets. The program begins with entering the list of required widths and lengths.

Other machines may be simulated, however, the nesting technique is unchanged. Machines having such features are common in light metal fabrication, joinery using saws, glass cutting and many other applications. The essential feature of such a machine is that it does not cut re-entrant corners it cuts completely through a workpiece at every operation, and every offcut is itself a rectangle. Covers sheared and sawn processing with kerf width allowance for saw blade. Handles multiple stock sizes and parts consolidation. Use for metal, wood, glass, marble, plastics and 'like' products for maximize yield. Powerful nesting algorithms deliver substantial savings in seconds and the program also generates pick lists.

0 kommentar(er)

0 kommentar(er)